iVolve Mine4D Maintenance™

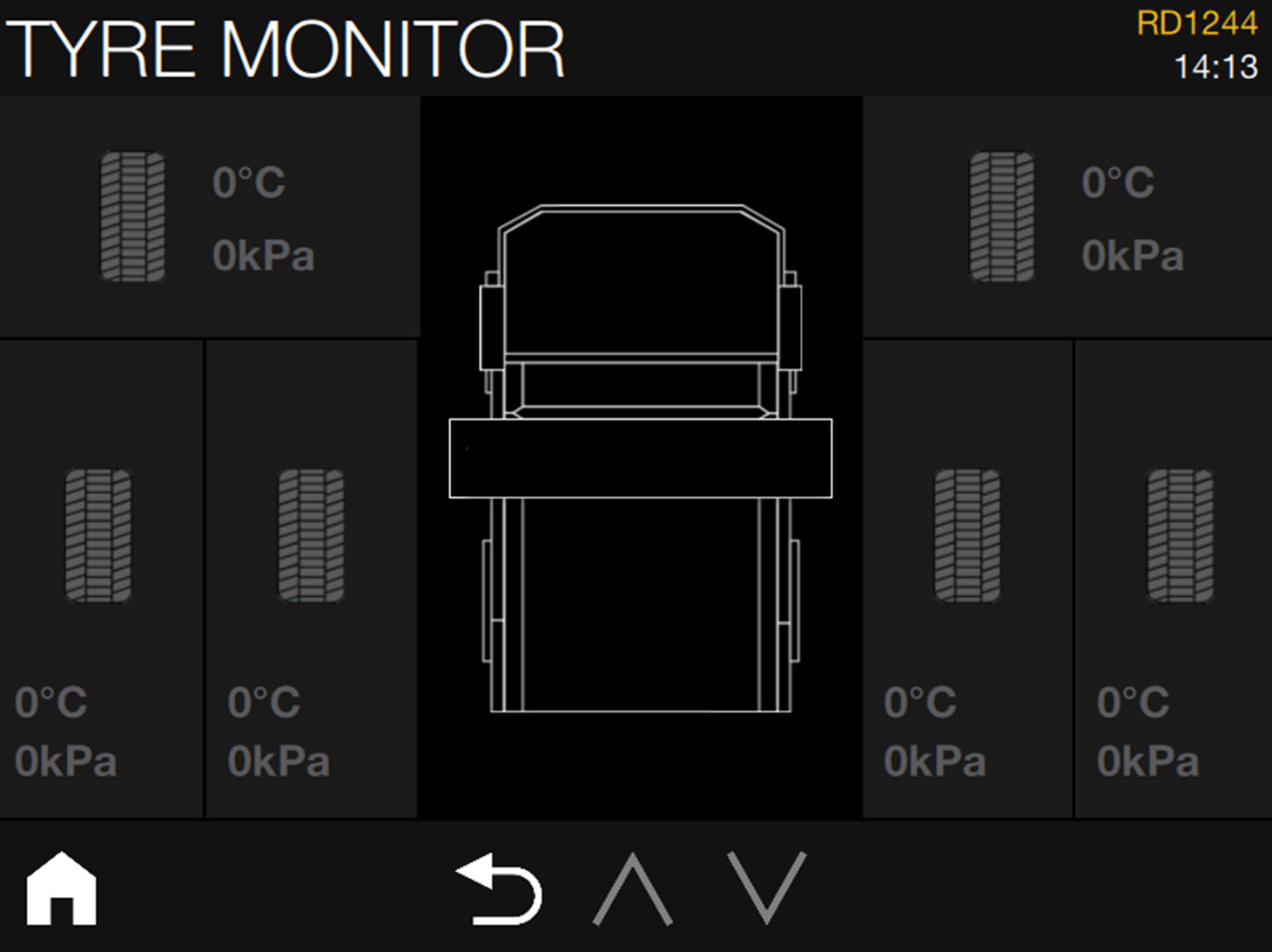

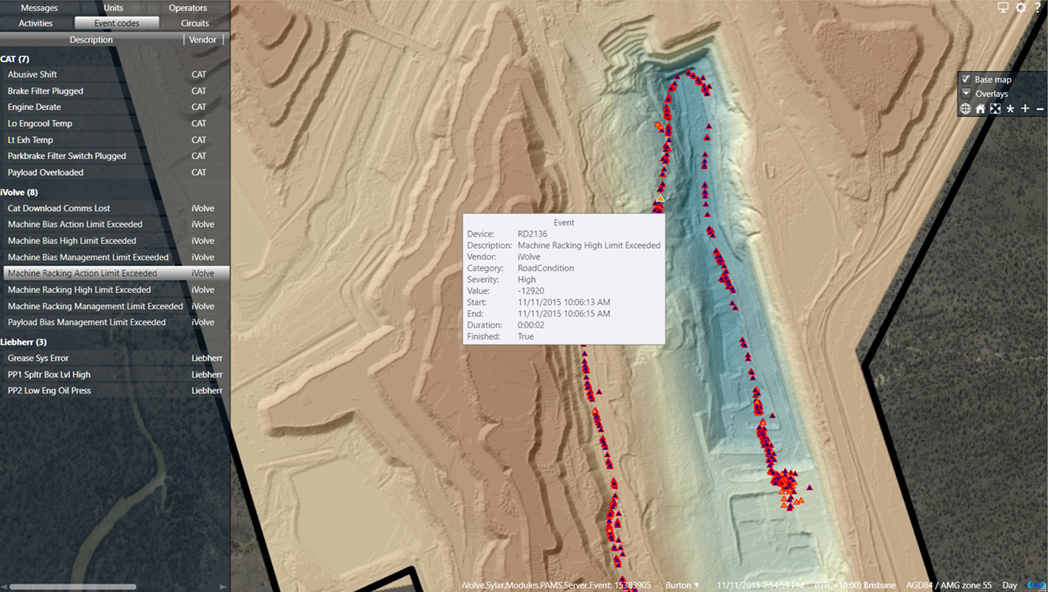

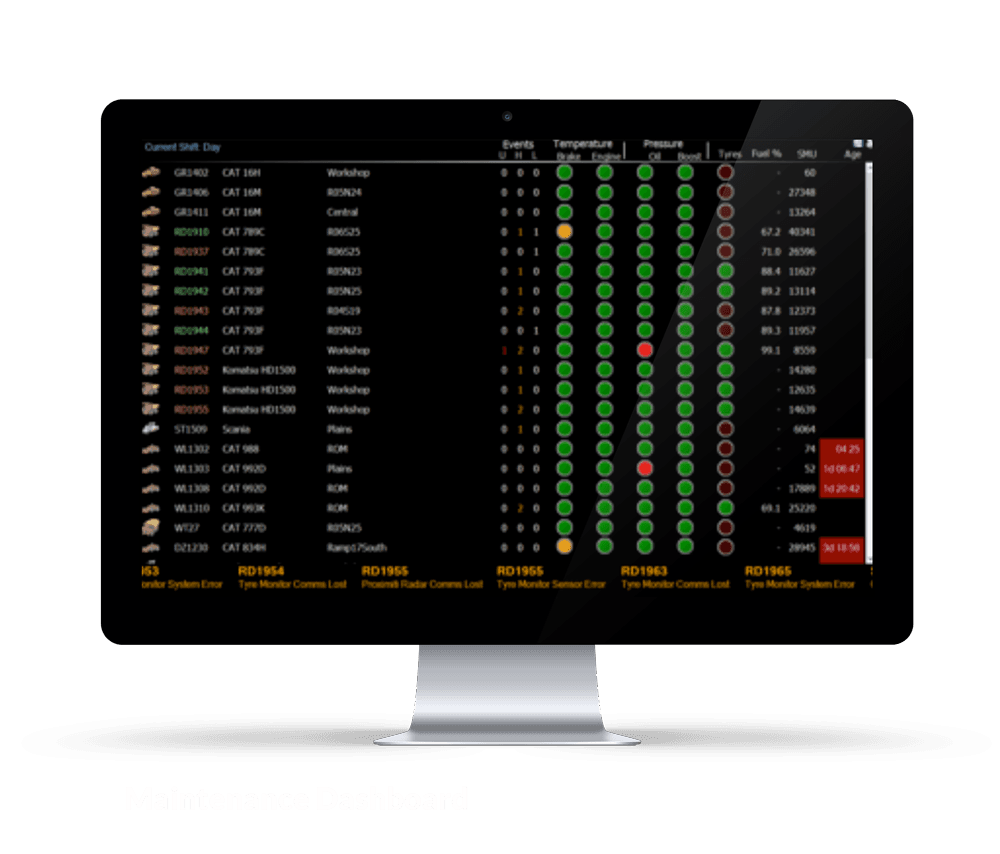

Utilising on-board vehicle management systems, iVolve Mine4D Maintenance provides real-time equipment health data feeds. This data is displayed graphically via iReport dashboards at fleet and individual asset levels, with full data history available for informal and scheduled reporting.

In the event of site-specified alerts, Maintenance provides onscreen alerts within iControl providing true, real-time decision making capability. Maintenance will improve your machine availability while decreasing maintenance and lost production costs associated with in-service failures.